Product Description

A chemical ton bag refers to a flexible intermediate bulk container (FIBC) specifically used for transporting, storing, and transferring bulk chemical raw materials or products. Also known as a ton bag, they are widely used in the chemical industry due to their large capacity (typically ranging from 0.5 tons to 2 tons), relatively low cost, convenience of use, space savings, and labor efficiency.

The main features of the fine workmanship ton bags for chemical raw materials sold by our company’s manufacturer are:

Material: Usually made of polypropylene (PP) or polyethylene (PE) woven fabric, some are coated with film (such as PE inner lining) to enhance moisture-proof, anti-static or sealing performance.

Capacity: Common specifications range from 500kg to 2000kg (1 to 2 cubic meters), and can be customized.

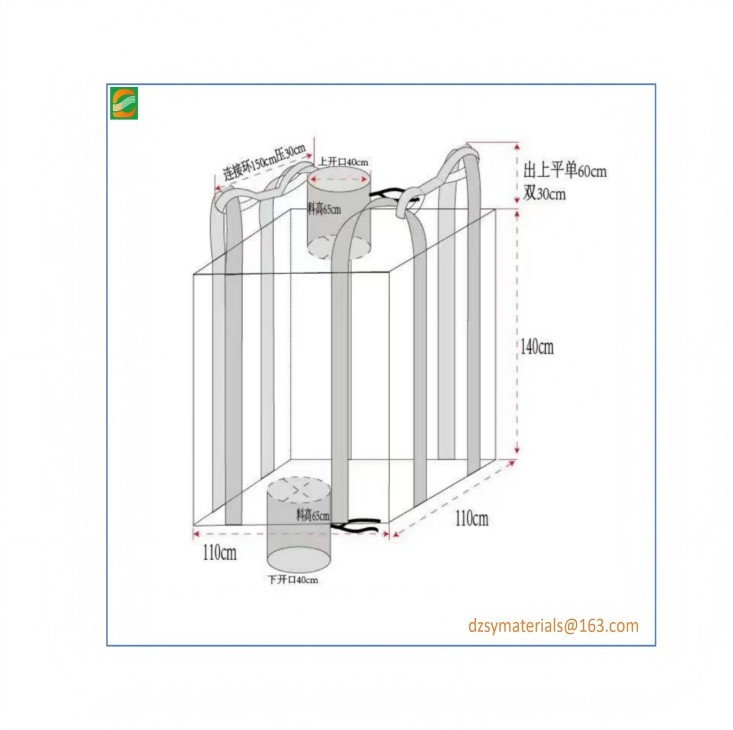

Structure: Top loading port, bottom unloading port (with/without valve), and designed with lifting straps or forklift slots.

Safety: Some ton bags are treated with anti-static (Type C/D), flame retardant or UV-resistant properties, and comply with chemical industry standards (such as UN certification).

Application in the chemical industry

Raw material transportation: Granular and powdered chemical products (such as plastic particles, fertilizers, soda ash, etc.).

Packaging of hazardous materials: Must comply with international standards such as IMDG and ADR, and mark hazard symbols.

Special requirements: Acid and alkali-resistant coatings (such as HDPE lining), moisture-proof and oxidation-resistant (aluminum foil composite layer).

Selection Considerations

Compatibility: Verify the chemical compatibility between the chemical materials and the ton bag material (to avoid corrosion or dissolution).

Certification Requirements: Such as food grade (FDA), explosion-proof (ATEX), or environmental protection certification.

Handling Methods: The strength of the lifting straps and the design of the discharge port need to match the on-site equipment.

Common Issues

Electrostatic Risk: Conductive type tote bags (Type C) must be grounded for use.

Stack Limitations: Avoid overloading which may cause rupture. Generally, do not stack more than 2 to 3 layers.