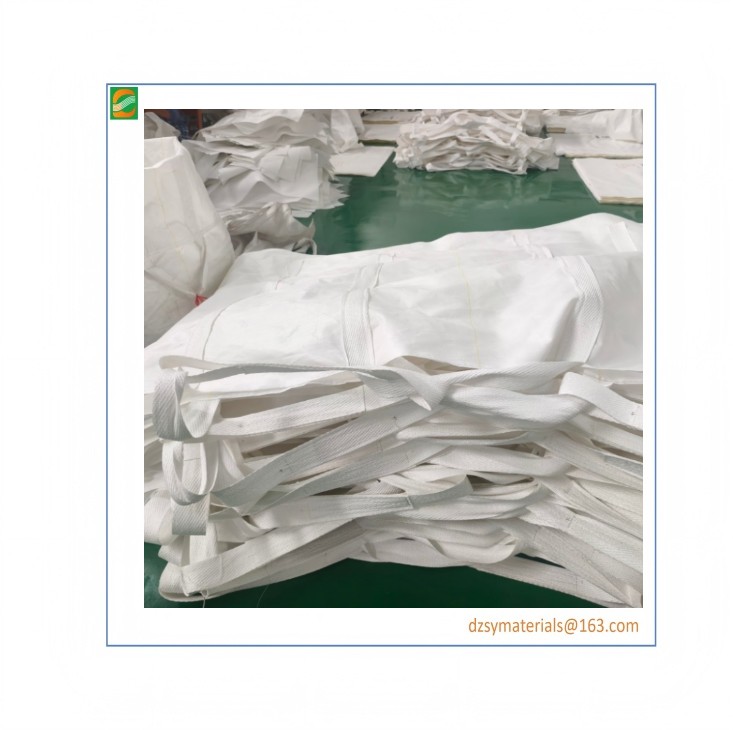

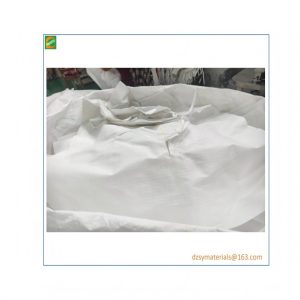

Product Description

Basic Structure and Material Selection for Tonne Bag Loading and Unloading Ports

- Structural Design – The loading port is usually located at the top of the ton bag, with a circular or square design. The diameter is recommended to be φ300-500mm (in accordance with GB/T 10454-2000 standards), facilitating quick loading; the unloading port is mostly located at the bottom and requires a loading/unloading valve or drawstring structure, with an aperture generally of φ200-400mm. – Key parts need to be reinforced, such as sewing double-layer fabric or adding PP/PE reinforcing ribs to prevent tearing.

- Material Requirements – The main material is 150-200g/㎡ polypropylene (PP) woven fabric, which has wear-resistant and moisture-proof properties; the inner lining can be PE film, which prevents powder leakage. – The sewing thread should use high-strength polyester thread (tensile strength ≥ 50N), with a needle spacing controlled at 8-10 stitches/10cm (refer to ISO 13934-1 standard).

Production Steps and Key Process Points

- Cutting and Sewing – Cut the fabric according to the design size, with a seam allowance of 1.5-2cm; the edge of the loading port needs to be rolled and sewn, with a width of ≥ 3cm to enhance durability. – The unloading port is recommended to adopt a “U-shaped” or “butterfly knot” type drawstring design, with a drawstring length of ≥ 1m to ensure sealing.

- Quality Control – Test Standards: After loading, suspend for 48 hours (refer to ASTM D5265), check if the sewing thread is loose, and if the fabric is deformed. – Common Issues and Solutions: If there is a leakage, an additional heat sealing process (temperature 180-200℃) can be added to seal the joint.

Customization Plan and Industry Application

- Special Design for Powder Materials – Add a dust-proof cover or flange interface to the unloading port to prevent dust; the recommended diameter is ≤ φ300mm to reduce residue.

- Optimization for Particle Materials – Use a conical unloading port (inclination angle ≥ 45°) to promote smooth unloading, and when necessary, apply a smooth PE coating on the inner lining.