Product Description

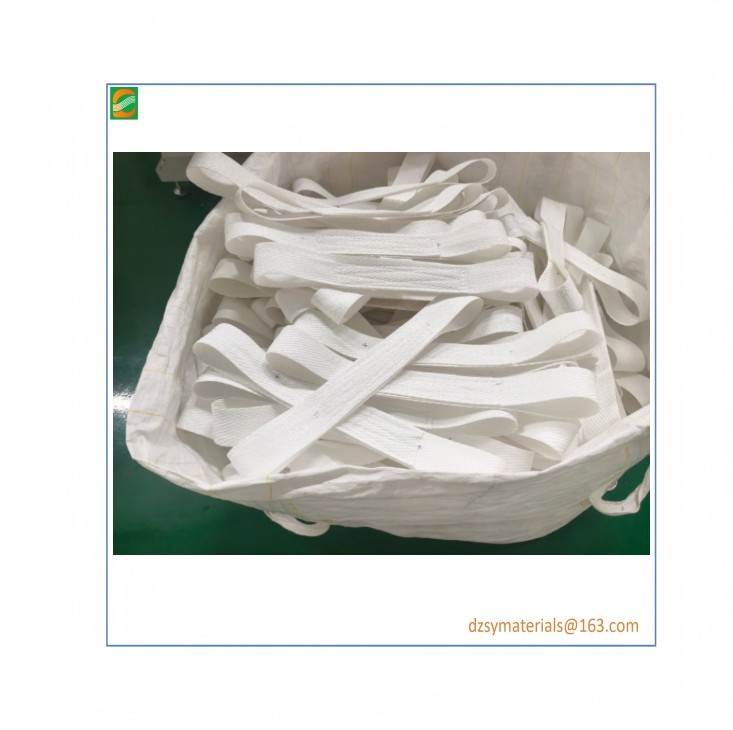

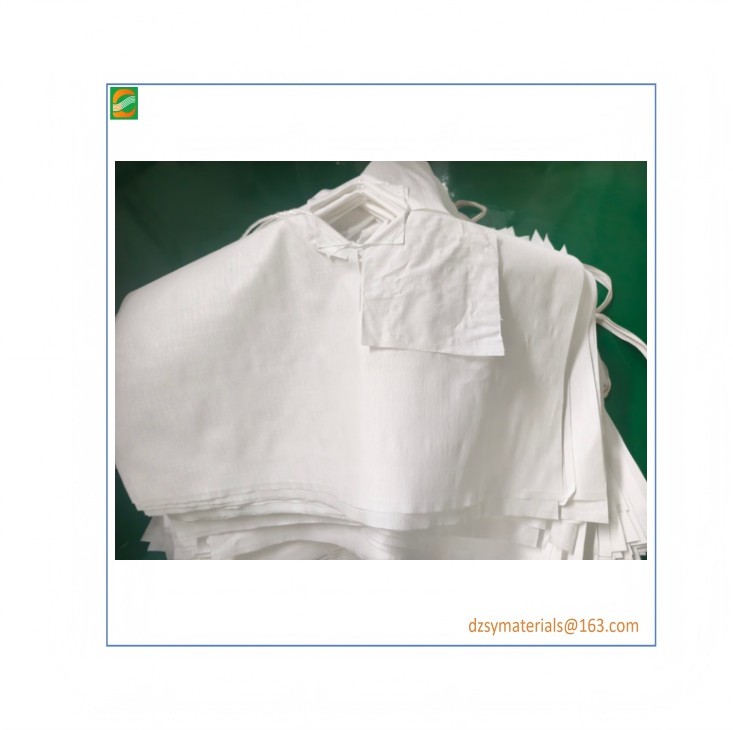

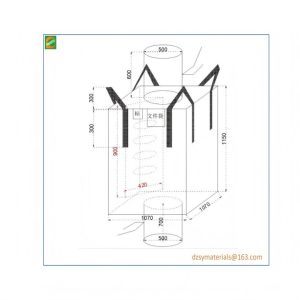

FIBC bags are made mainly from polypropylene, with a small amount of stabilizing additives mixed evenly. After being melted and extruded into plastic films by an extruder, they are cut into threads and then stretched and heat-set to form high-strength, low-elongation PP original threads. These threads are then woven and laminated to form the base fabric of plastic woven bags. After being sewn together with straps and other accessories, they become ton bags.

FIBC bags can be classified by shape as follows:

- Round ton bags: They are designed in a cylindrical shape, with high space utilization, and are suitable for loading granular or free-flowing materials (such as grains and chemical raw materials). Common diameters range from 80 to 120 cm, and heights from 100 to 150 cm (refer to GB/T 10454-2000 standard).

- Square ton bags: They have a cubic structure, strong stacking stability, and are convenient for storage and transportation. They are often used for solid materials such as building materials and mineral powder.

- U-shaped ton bags: They have a U-shaped bottom design, ensuring no residue when unloading, and are commonly used for high-value powder products (such as titanium dioxide).

Industries suitable for ton bag packaging include: chemical raw materials, pharmaceutical raw materials, plastic raw materials, food additives, feed additives, metallurgical powder, mineral powder, and refractory materials.