Product Description

Bulk bags play a significant role in many industries that require the transportation or storage of large quantities of products, featuring robustness and flexibility. However, in some high-end chemical products that are susceptible to static electricity, humidity, temperature and other factors, traditional bulk bags may not meet the requirements. At this point, it is necessary to consider bulk bags with aluminum foil inner bags. The aluminum foil inner bag bulk bag, also known as aluminum foil ton bag, aluminum foil bulk bag, aluminum-plastic composite heavy-duty bulk bag, and aluminum-plastic inner bag, etc., is made of an aluminum foil high-barrier inner bag that can protect any product from deterioration caused by moisture, oxygen, ultraviolet rays, extreme temperatures, and odors.

Aluminum foil ton bags are generally divided into base layer, functional layer and heat seal layer:

- Base layer: mainly serves for aesthetics, printing and moisture resistance, etc.;

- Functional layer: mainly serves for barrier and light avoidance, etc., such as VMPET, NY, AL materials;

- Heat seal layer: directly contacts with the packaged items and has functions such as adaptability, resistance to penetration and good heat sealing property.

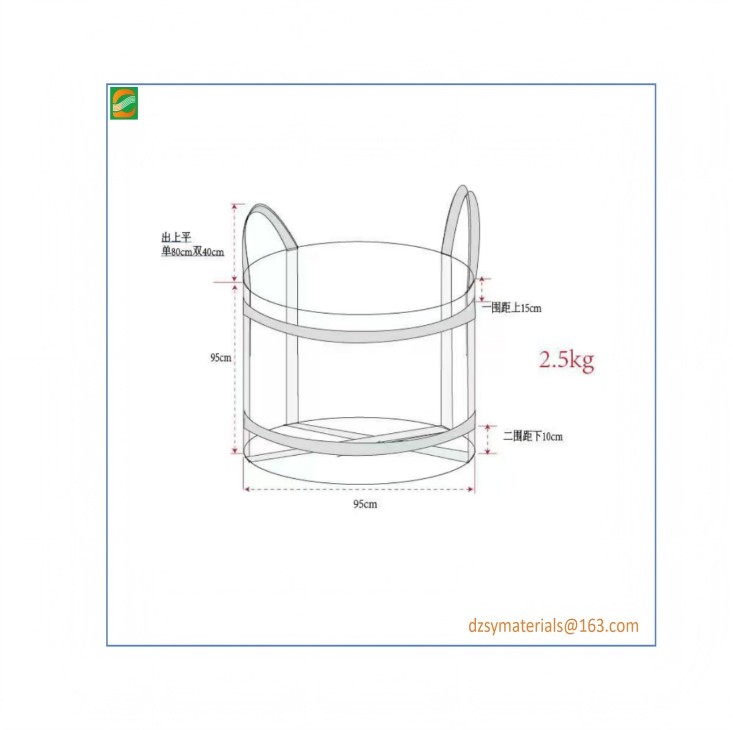

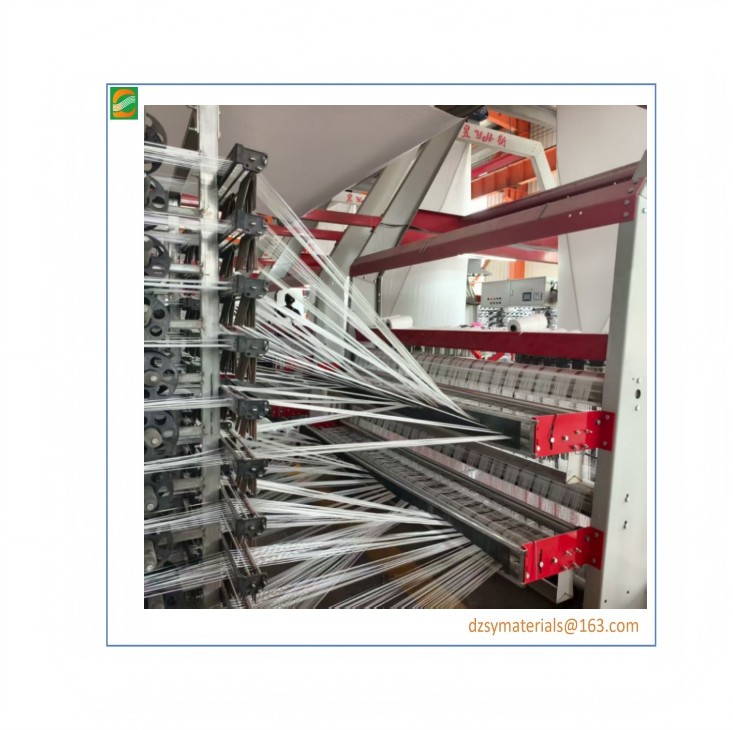

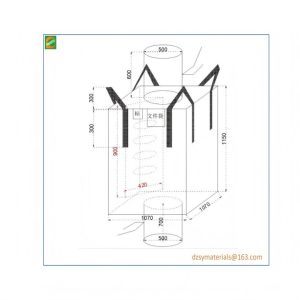

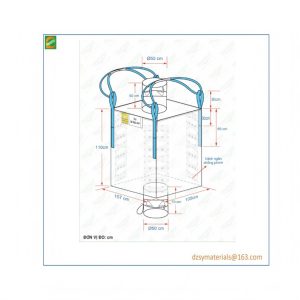

The aluminum foil inner bag is combined with the outer PP woven bag through sewing processing after one or more dry lamination processes, thus forming a composite packaging with certain functions, with an average load capacity of 600-2000 kilograms.

The performance of the aluminum foil barrier layer depends on its water vapor and oxygen transmission rate, which is lower than that of other flexible packaging materials. It can prevent moisture and gases from entering or leaving the product, thus preserving the product better and for a longer time. The applicable product range includes: special metal chemical raw materials, chemical modified plastic particles, engineering plastic particles (such as one-step and two-step silane cross-linked cable sheath materials, low smoke and halogen-free), TPU/TPV/PA12/PA46/PA66 nylon and other plastic particles, biodegradable particles, new energy lithium battery positive and negative electrode raw materials (such as cobalt hydroxide, lithium manganate, lithium iron phosphate, etc. lithium-ion battery positive and negative electrodes and ternary precursor materials), etc.